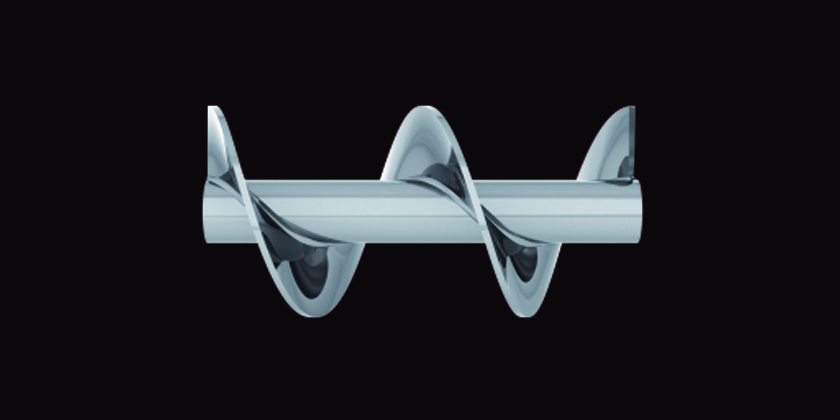

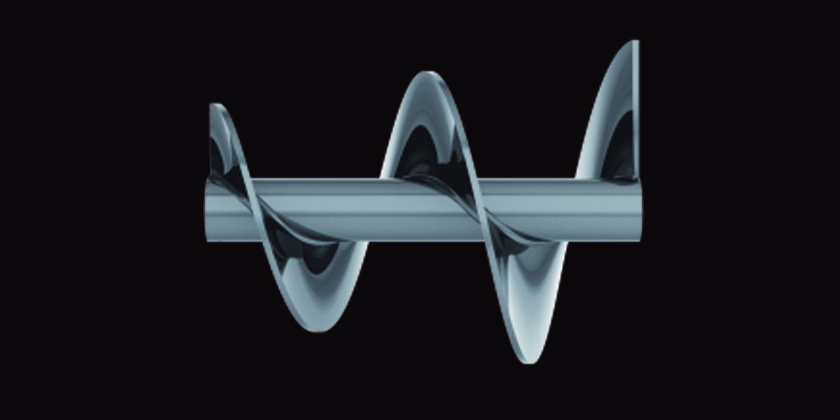

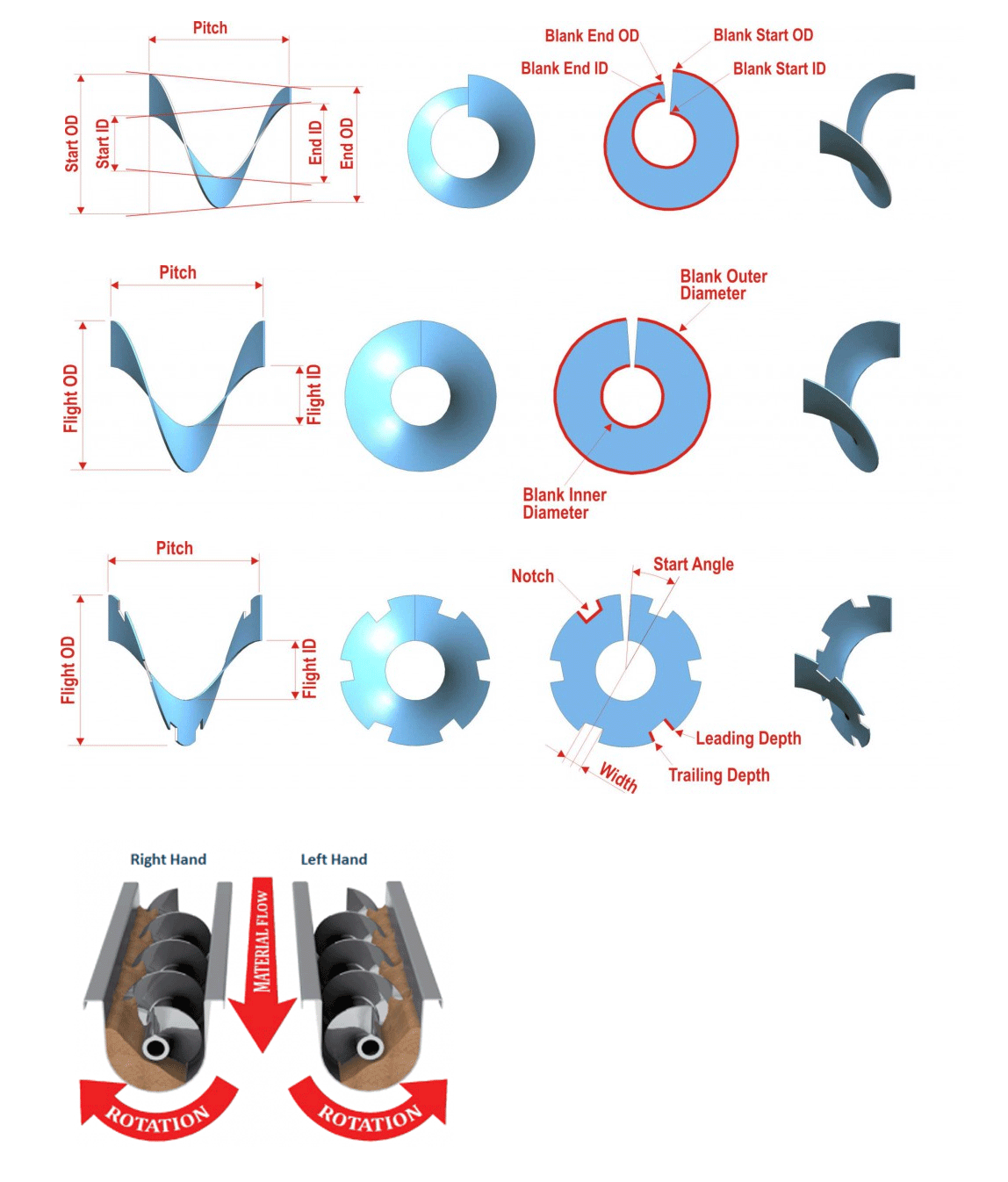

Standard flight

Screws with a pitch spacing equal to the diameter are considered standard and are suitable for most conveyors of conventional horizontal design.

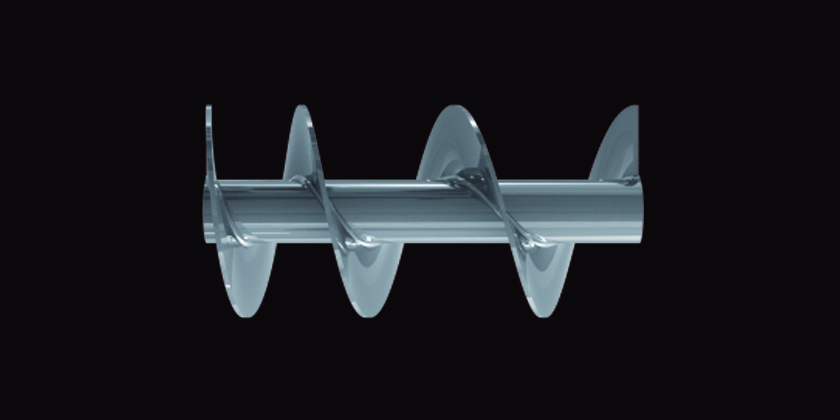

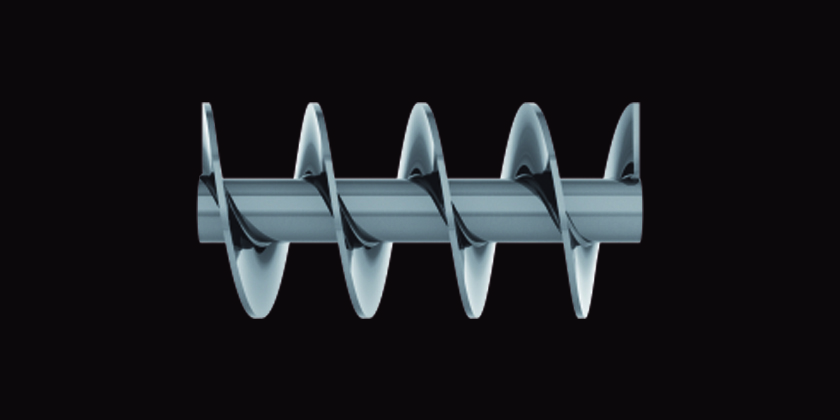

Variable pitch flight

Variable pitch flights are used to control the amount of material drawn down along the length of a hopper. By increasing the pitch at each flight along a screw you can incrementally increase the volume of product that is allowed to enter the screw.

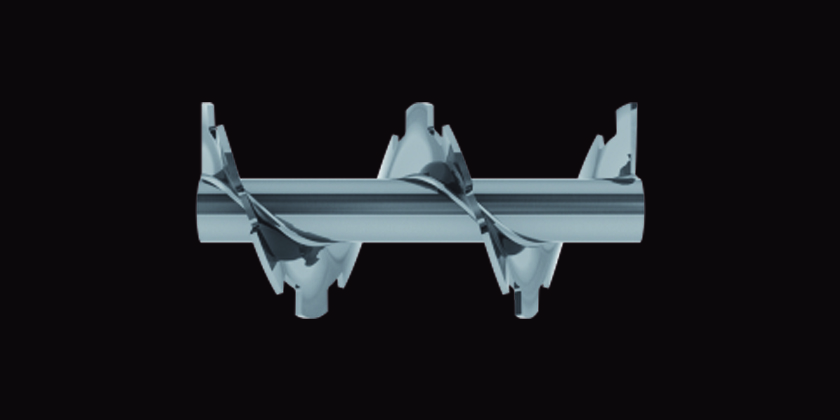

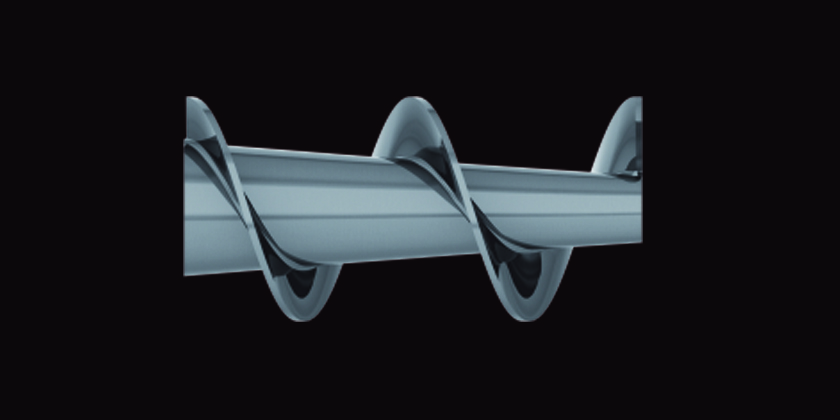

Notched flights

Notched flights are used to provide a gentle mixing action. Notched flights are useful in blending different materials during the conveying process.

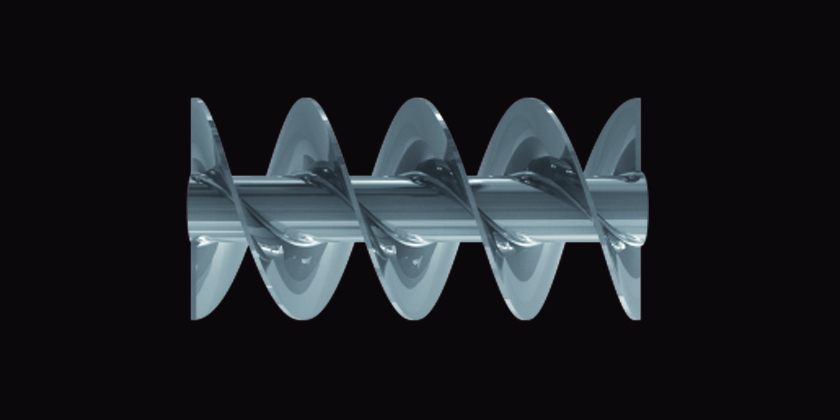

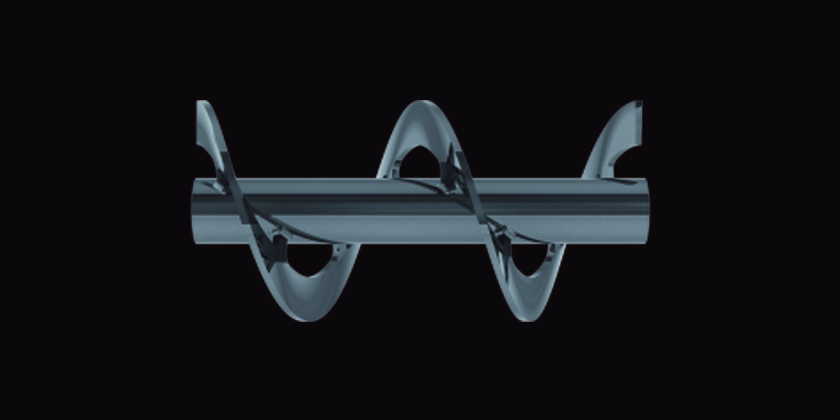

Double start flight

Double start flights are used to accelerate the conveying process at the conveyor inlet and even out the pulsing effect at the outlet. They are also typically used in drilling and post-hole augers to equalise the torsional forces on the auger.

Tapered flight

Tapered flight spirals provide a continuous incremental change in swept volume of the screw. This promotes even drawdown in a full hopper situation. Tapered flights leave residual material in the conveyor unless the casing is tapered to suit.

Short pitch flight

Short pitch screws are used in inclined conveyors. They are also used to control the feed at the inlet and to reduce flushing of free flowing materials. The shorter the pitch the more efficient is the screw.

Coned flight

Conical flight centres provide a continuous incremental change in swept volume of the screw. This promotes even drawdown in a full hopper situation. Combined with variable pitch the coned screw provides the best possible solution to even hopper drawdown. Standard troughs can be used with coned flights.

Ribbon flight

Ribbon flights with integral support legs are used for sticky or cohesive materials that tend to build up on the flight-pipe interface.

Centreless flight

Centreless flight are they are mounted in the conveyors without the need of central and terminal supports increasing its transport capacity and reducing block resistance. These flights allow higher rates of filling and lower laps/min, assuring less usury and lower time of maintenance. This system make these flights ideal for whiskers and irregular products, waste sticky materials with different size, volume or moisture and dry solids as shavings, sawdust, pellet, mud, garbage, chemical substances.

F.A.Q.

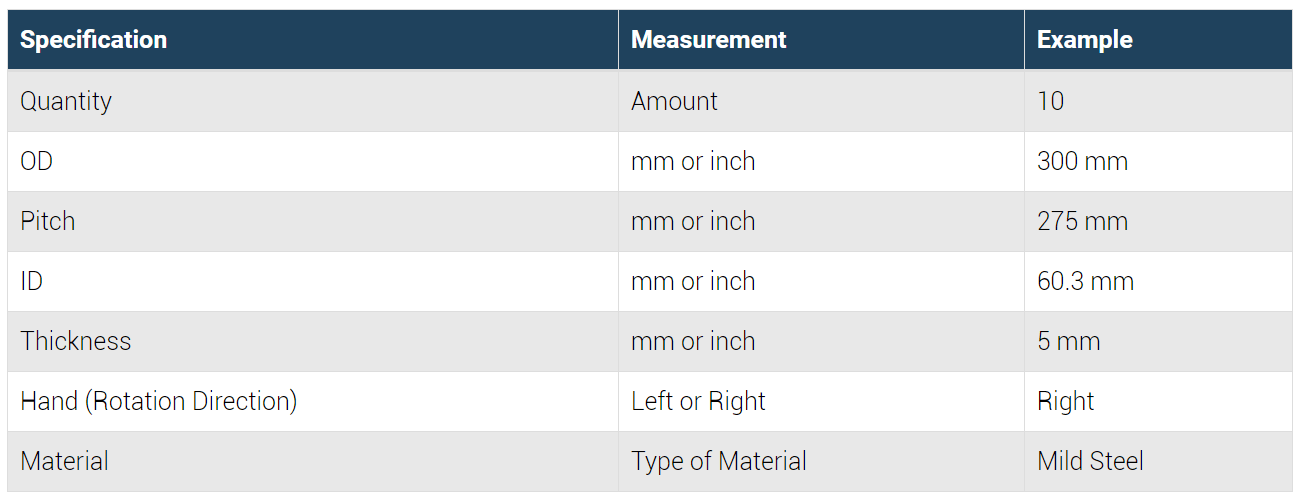

150 mm to 1200 mm diamater

3 mm to 35 mm thickness

- Stainless Steel

- Wear Resistant Steel (Hardox 400 – Hardox 450 or equivalent)

- FU.S.A.L. Coated Wear Plates - Other as desider